Important Factors To Consider for Making Certain High Quality and Durability in operation Engines

When considering the purchase of an utilized engine, guaranteeing its top quality and longevity requires a multifaceted method. Maintenance background is a critical aspect, as it supplies understanding into the engine's previous treatment and prospective future integrity. Beyond paperwork, a comprehensive examination of physical components-- such as belts, hose pipes, and seals-- can expose covert concerns. Efficiency screening is likewise important, using a snapshot of the engine's operational efficiency. Recognizing the nuances of these evaluations and their implications can be complicated. What are the crucial methods that can be utilized to navigate this detailed assessment process properly?

Engine Background Analysis

In the world of made use of engines, a thorough engine background examination is vital to ensuring high quality and integrity. Recognizing an engine's past can give crucial understandings right into its performance capacities and possible future long life.

Engines that have actually gone through significant repairs might have underlying problems that can resurface. Taking a look at the engine's mileage can serve as an indication of wear and tear. An engine utilized largely for long-distance freeway driving might be in better problem than one subjected to frequent stop-and-go city web traffic.

Essentially, an exhaustive examination into an engine's background is essential for making educated acquiring choices. used engines for sale.

Comprehensive Assessment Overview

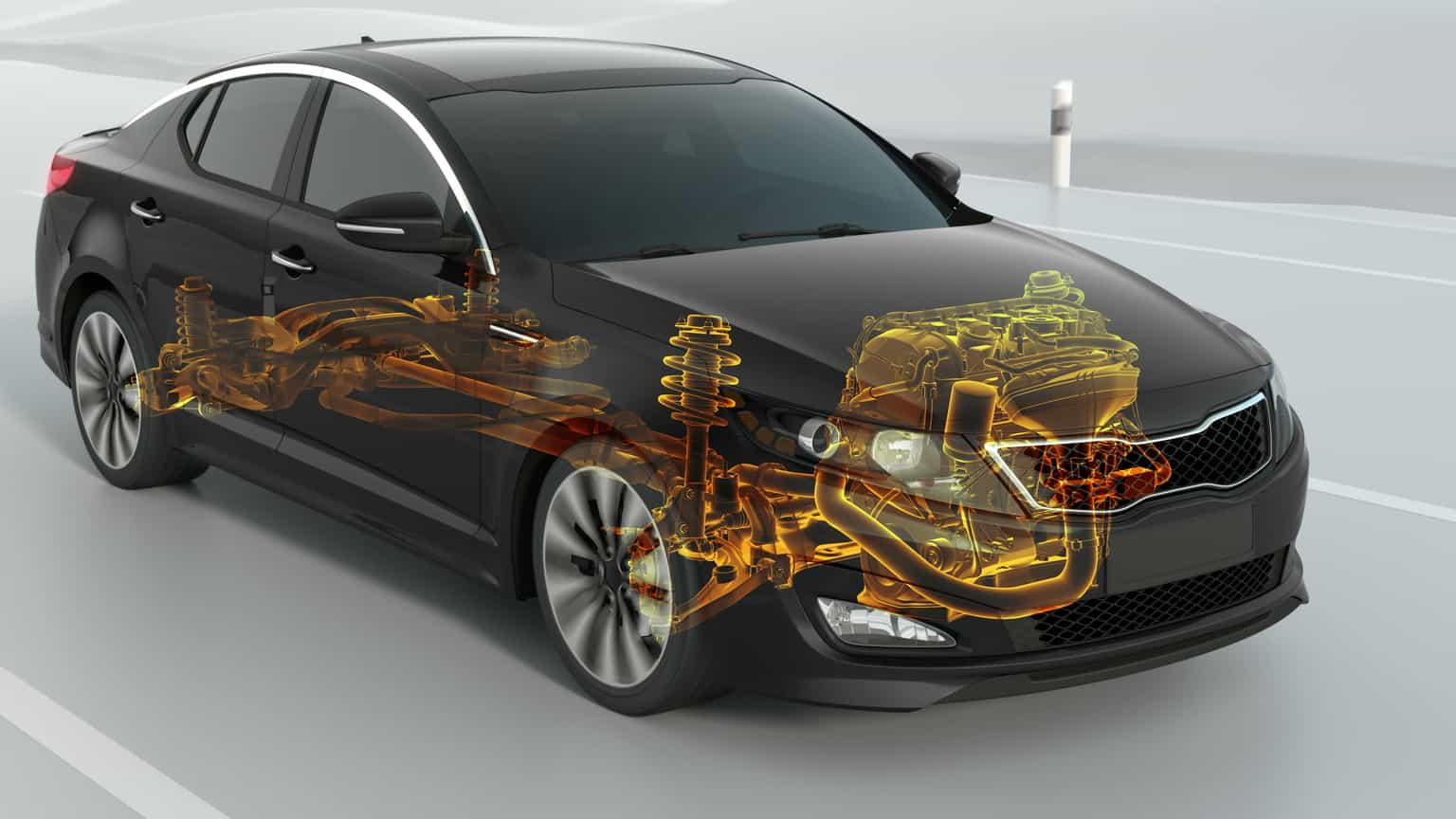

While comprehending an engine's background gives important context, an extensive assessment is the following action to guarantee its existing condition straightens with historical information. The evaluation needs to begin with an aesthetic assessment, looking for indicators of leaks, rust, and uncommon wear. Examine the outside for oil spots or coolant marks, which may suggest underlying concerns.

Next, examine the engine's mounting system for any loosened screws or abnormalities that can influence efficiency. Pay attention to the condition of belts and hose pipes, as these elements are vital for optimum engine functionality. Take a look at for splits, fraying, or any indications of deterioration.

Recognizing Damage

Identifying indications of wear and tear is crucial for evaluating a made use of engine's durability and reliability. It entails a precise exam of various engine parts to determine their existing state and potential future efficiency.

Another important aspect is examining the engine's seals and gaskets. In addition, uncommon sounds during engine operation, such as knocking or ticking noises, might show inner damage or extreme wear on relocating components like pistons or bearings.

The problem of belts and hoses is equally important, as they play an essential duty in the engine's overall function. Cracked or frayed belts and brittle hose pipes are indications of maturing that can cause engine failing if overlooked. Analyzing the oil condition and filter can provide insights right into previous upkeep practices, as unclean oil or clogged up filters suggest neglect and accelerated wear.

Efficiency Testing Fundamentals

Examining the deterioration of engine elements sets the phase for a comprehensive analysis via performance testing. Efficiency testing functions as an important index procedure in identifying the operational honesty of an utilized engine. By replicating real-world problems, it analyzes the engine's capability to deliver power successfully and accurately. Key metrics consist of horse power, torque, fuel efficiency, and emissions levels. This information offers valuable understandings right into the engine's existing efficiency and assists identify possible problems that may not be quickly noticeable.

Using dynamometers is a common technique in efficiency testing. These tools gauge the engine's outcome across various problems, offering an in-depth profile of its functionality. Furthermore, on-road screening matches dynamometer evaluations by observing engine behavior under common driving circumstances, ensuring it satisfies the needed standards for both safety and security and effectiveness.

These devices examine engine monitoring systems, recognizing faults in digital parts that might influence efficiency. Comprehensive screening not just validates the engine's functional standing yet additionally help in forecasting future maintenance needs.

Upkeep and Treatment Tips

Correct upkeep and care are important to extending the life expectancy of an utilized engine and ensuring its constant efficiency. Normal oil adjustments are extremely important; making use of the supplier's suggested oil type and quality can avoid too much damage. Furthermore, oil filters need to be changed concurrently to maintain optimum lubrication and sanitation within the engine.

Keeping an eye on fluid levels, including coolant, transmission liquid, and brake liquid, is crucial. Making certain these liquids are at appropriate degrees assists avoid overheating and other mechanical concerns. Evaluating belts you can try here and pipes for signs of wear, such as fractures or fraying, can avoid possible failings that might bring about expensive repairs.

Routine examination of the air filter is likewise necessary, as a tidy filter guarantees reliable air movement and combustion, thereby maximizing engine performance. Ignition system ought to be inspected and replaced when required to maintain reliable fuel burning and prevent engine misfires.

Last but not least, regular diagnostic checks making use of professional devices can recognize potential problems before they end up being significant issues. By sticking to these upkeep and care ideas, made use of engine proprietors can ensure their engines stay reliable, effective, and capable of executing well over an extended period.

Final Thought

Comments on “Leading Tips for Inspecting Used Engines for Sale Prior To Making a Purchase”